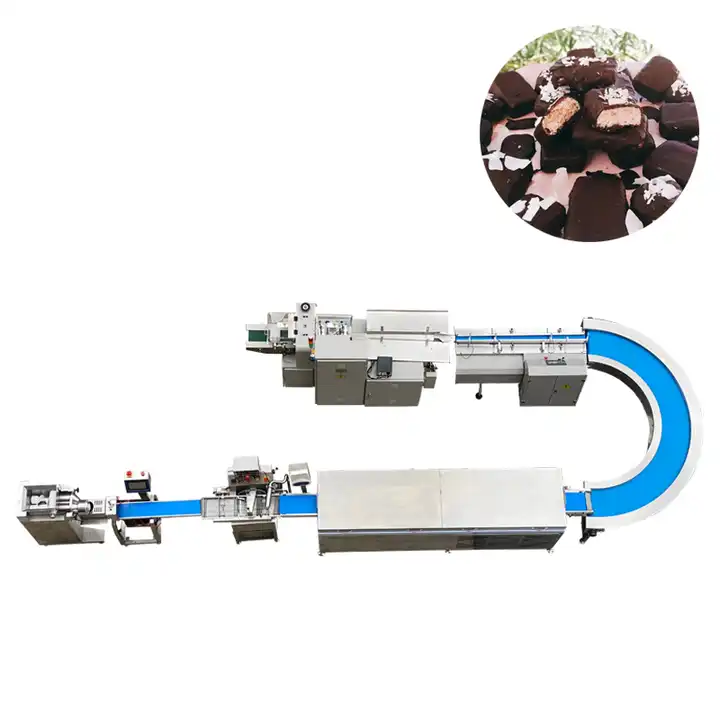

Energy bar machinery

Classification:

others

- Product Description

-

Shanghai Papa Industrial Co., Ltd. is a leading SHRIMP bread maker in China. Shanghai Papa Industrial Co., Ltd. not only has excellent testing equipment, but also has strong technical strength, dedicated to the production and research of machines. Our nutrition bar making machines come in a wide variety, with superior quality, reasonable prices, and stylish designs, widely used in the food industry.

Model

P307

Output

20-100pcs/min

Product weight

10-250g

Power

4.5kw

Voltage

220V/380V

Dimension

5800*950*1450mm

Weight

500kg

The SHRIMP protein rod making machine is a newly designed machine based on our customers' requirements for smaller size and lower cost. This machine can make protein bars, nutrition bars, power bars, etc. Our P307 protein stick making machine is a new type of extruder designed specifically for making various types of sticks, such as protein sticks, fruit sticks, energy sticks, coconut sticks, chocolate bars, etc. Composed of an extruder, cutting machine, and conveyor, our SHRIMP protein powder making machine is a multifunctional stick making machine, also known as a nutrition stick making machine, fruit stick making machine, coconut stick making machine, biscuit making machine, snack stick making machine, and energy stick making machine. Mechanical, chocolate bar making machine, bar cold extrusion machine, mini electric bar cutting machine.

Detailed explanation of production process

1. Raw material mixing and transportation

-Dry and wet materials are separately fed into the mixer through a screw conveyor, with a mixing uniformity of ≥ 98%.

-The mixed material is transported to the forming device through a high-pressure pump to ensure continuous feeding.2. Forming and cutting

-The molding device adopts modular molds and supports quick switching between different shapes (square, circular, wavy).

-The automatic cutting machine is driven by a servo motor, with a cutting accuracy of ± 1mm and a matching production line speed of 20 meters per minute.3. Coating and Packaging

-After coating, the product enters the vibration conveyor belt to shake off excess chocolate and ensure weight consistency.

-The packaging machine adopts nitrogen filling technology (oxygen residue ≤ 1%) to extend the shelf life, with a heat sealing temperature of 140-160 ℃ and a sealing strength of ≥ 3N/15mm.Why choose PAPA MACHINE?

Professional knowledge: With years of experience in the food processing industry, Papa Machine has unparalleled expertise in protein stick production technology.

Innovation: We are committed to innovation and constantly invest in research and development to improve the performance and capabilities of our machines.

Customization: Our machines can be customized to accommodate various formulas, formulations, and production volumes, meeting the unique requirements of each customer.

Quality: We adhere to strict quality standards throughout the entire manufacturing process to ensure that our machines are reliable, durable, and long-lasting.

Support: Our professional team provides comprehensive support, including installation, training, maintenance, and technical assistance, to ensure the smooth operation and optimal performance of our machines.

Contact us:

Email: sales@papamachine.com

Mob/whatsapp:0086-13818791174

Wechat:13818791174

Tel:+0086-21-67188079

Product Inquiry

If you have any questions or needs, please leave a message or contact us and we will reply you as soon as possible.

+8613818791174

+8613818791174 sales@papamachine.com

sales@papamachine.com